CO Activated Carbon Adsorption Catalytic Combustion Equipment

Views:

1000

Category

Product introduction

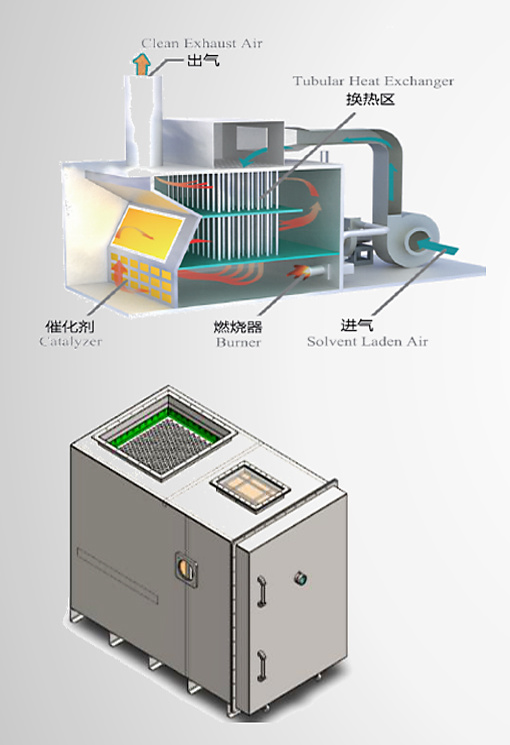

The catalytic combustion system consists of a heat exchanger, combustion chamber, and thermal storage unit. Catalytic combustion technology achieves >95% VOC removal efficiency at relatively low temperatures (300–500°C), offering energy-efficient and highly effective exhaust gas treatment. Using catalysts, organic pollutants undergo flameless combustion at low ignition temperatures, oxidizing into CO₂ and H₂O while releasing significant heat.

| Target VOCs | Toluene, xylene, ethyl acetate, propyl acetate, butyl acetate, PMA, butanol, hexane, MIBK. |

| Concentration Range: | ≥1000mg/m³ 以上 |

| Requires Verification | Styrene |

| Prohibited Components | Sulfur, phosphorus, halogens. |

| Applications Industries | Food processing, electronics, rubber/plastics, painting, printing, chemicals. |

Technical Features

| Parameter | Specification |

|---|---|

| Oxidation Temperature | 300°C |

| Heat Exchange Efficiency | 65% (tubular/plate heat exchanger) |

| Treatment Efficiency | 90–99% |

| Max. Operating Temperature | 500°C |

| Safety Systems | LEL monitoring, explosion-proof discs, flame arrestors, PLC-controlled overtemperature protection |

| Footprint | Compact design |

| Operational Mode | Suitable for intermittent operation |

Additional Advantages:

Rapid Heating: Quick startup and energy-saving performance.

Low Heat Loss: High thermal efficiency.

Long Service Life: Reduced operational costs.

Stable Flameless Combustion: Safe and reliable operation.

Project Case: Zhejiang Chemical Fiber Group Co., Ltd.

1、Waste Gas Source: EPS foam production process.

2、Main Pollutants: Pentane, styrene.

3、Airflow Capacity: 5,000 Nm³/h.

4、Pollutant Concentration: 800–1,200 mg/m³.

5、Equipment Configuration: Catalytic combustion system.

6、Performance:

Adsorption Efficiency: ≥90%.

Oxidation Efficiency: ≥95%.

7、Compliance: Meets Emission Standards for Pollutants in the Synthetic Resin Industry (GB 31572-2015).

Keyword:

Environmental Protection Equipment

Product consultation

Free product brochure available upon providing your contact information.